How can I help you?

The form has been sent successfully.

The contact person will contact you as soon as possible.

Unfortunately, an error has occurred when sending.

Please try again later.

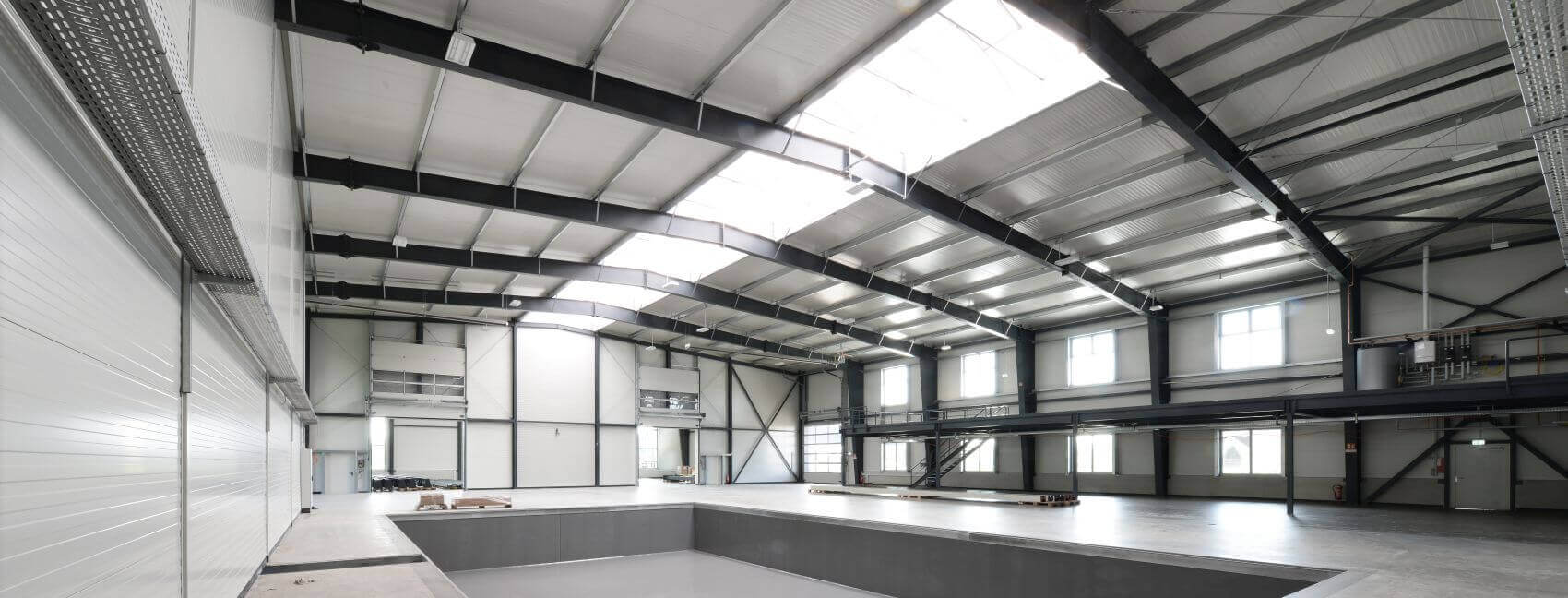

Hall construction

Build halls with PEM.

As a quality provider we have already successfully realised thousands of hall construction projects, and principals and planners are convinced by our expertise, reliability, and service. Whether it be a steel hall or industrial building, we will realise your project on time and in high quality. The earlier we are integrated into the hall construction project the more the principals and planners benefit from our expertise. This way we develop the optimal solution together. Our scope of services in hall construction usually starts from the top edge of the foundation.

This is why PEM Buildings is the right partner for hall construction

- Economical hall construction due to individual planning

- Optimised and short project processing time due to high degree of prefabrication

- Ability to react swiftly because of regional presence

- Cost certainty thanks to fixed prices and reduction of interfaces

- Concentration on daily business due to professional execution of construction work

- Short decision-making channels due to only one contact

- Economical operation due to sustainable and energy-efficient hall building concepts

Quality and safety management system

PEM Buildings is committed to quality – on many levels. Our highest principles such as customer satisfaction and high-quality hall construction management are ensured by our quality and safety management system: The certifications according to ISO 9001:2015 and SSC**:2011 confirm the quality management of PEM Buildings which has been successful over the years.

Every day we endeavour to retain the trust which our customers have placed in us. With this seal we give both existing and potential customers the certainty that with PEM they are building with the right partner. >> You can find more information on the QM & SCC system at the website of the certification company TÜV Süd.

More information on hall construction is provided by our reference folder PEM Highlights

This is how beautiful hall construction can be!

Steel hall

Steel, the ideal construction material.

Steel is a particularly versatile, durable, and clean construction material. It offers you numerous advantages, such as for example high cost-efficiency based on service life, as well as easy assembly, dismantling, and extension.

PEM Buildings uses exclusively high-quality materials for steel construction which correspond to the latest standards. For example, the full hot-dip galvanising of PEM steel constructions prevents corrosion damage. The PEM steel halls convince with their long service life.

Advantages of PEM steel halls

The use of steel in hall construction has been a success story for more than 50 years, which is to be attributed, above all, to the following reasons:

- 30% cheaper to purchase with the same service life

- Low production time and swift assembly due to a high degree of prefabrication

- Low-maintenance

- Slim design

Our services for your PEM steel hall

Based upon your individual usage requirements and the necessary dimensions, our experienced PEM experts will plan your steel hall and calculate the statics for the requirements of your site.

After the roof and wall systems have been clarified we produce steel construction drawings and pass these on to production. The individual steel elements are delivered “just in time” directly from production to the construction site. Hall assembly is carried out on site by PEM employees.

Make non-binding enquiries now

Industrial building

PEM industrial buildings and commercial halls that convince customers.

Thanks to its versatility is an ideal material for the construction of a very wide variety of industrial buildings and on top of this is also a convincing choice for hall construction, because of the short assembly times and good cost control. In addition to this, steel halls are flexible for changes of use or extensions.

The extensive selection of fittings include, among others, guttering, doors, roller shutters, sectional doors or high-speed doors, domed rooflights, window systems and much more. The customer determines the design of the hall facade and the colours given to the roof and walls.

Our services for your PEM industrial building

The requirements for industrial and commercial buildings are determined by the processes inside. We at PEM Buildings have learnt over the decades to take into account these individual needs in hall construction and offer this at competitive prices.

We realise hall construction projects for our customers in the following fields:

- Production halls

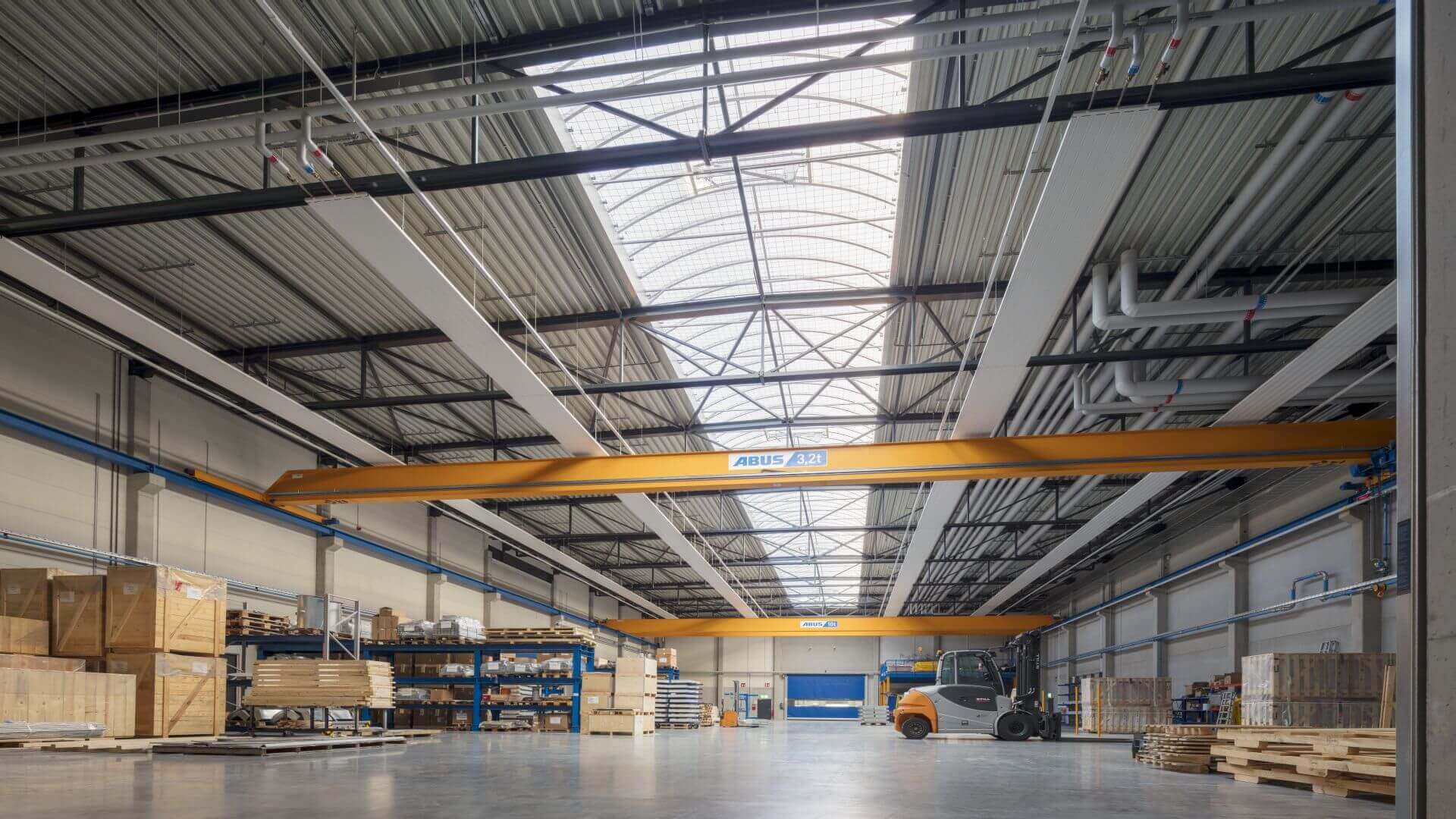

- Warehouses and logistics halls

- Shops

- Car dealers and workshops

- Sports halls

- Municipal buildings

Steel construction

Highest functionality and cost-efficiency

Choosing the optimal support structure system ensures the most cost-efficient solution as well as functionality. The support structure – whether it be welded plate girders with varying cross sections, timber frameworks, SIN corrugated web beams, profile steel or reinforced concrete supports with laminated timbers – also has a decisive effect on the hall’s appearance. Many factors influence which support structure system is most suitable for your steel hall:

- Span width

- Design height

- Ground conditions

- Foundation

- Snow loads

- Spacings of the structural frames

- Installations such as crane tracks, etc.

Functional steel construction

We equip the hall construction optimally with steel platforms, machine substructures, mast facilities, pipe bridges, etc. according to the individual usage requirements.

Roof & wall

PEM Buildings will also give you expert advice for the selection of suitable materials for the finish of your structure.

Wall cladding

- Double-shell wall construction with heat insulation in between

- Sandwich panels with PU foam insulation or mineral wool, laid horizontally or vertically (with visible or concealed fastening, sine wave corrugated sheet or microlined)

- Cassette wall with insulation and outer shell, trapezoid or sine wave corrugated sheet laid horizontally or vertically (smooth internal finish, laying without bay rail up to approx. 10 m bay distance)

- Aerated concrete with full heat insulation

Roofing

Roofing

- Single-shell trapezoidal corrugated sheet (supplemented with anti-condensation coating)

- Sarking insulation

- Double-shell trapezoidal corrugated sheet with insulation in between

- Sandwich panels with PU foam insulation or mineral wool

- Sliding clamp roofs

- Foil roofs

Installations

Crane and stairway installations and awnings

The additions and installations are an essential part of a successful new hall construction.

PEM plans and realises these services together with a large number of innovative and quality-conscious partner companies. Here it is important that the individual components are suitable for the hall construction and are coordinated with each other as regards constructional, fire-safety and functional aspects.

Skylight strips and domed rooflights

Natural light through the roof is the most effective way to supply your steel hall with daylight. For this one can use a continuous skylight strip arranged along the crown and/or from the crown to the eaves. The strip can feature fire exhaust flaps (in accordance with a fire safety report) which can also be used for daily airing and ventilation.

Alternatively or in addition to this, domed rooflights can be used in places to brighten areas of the hall. The hall’s domed rooflights can also be equipped as fire smoke extraction vents with a ventilation function.

Doors and gates

The size and type of the hall gates and doors depends on factors such as frequency of use, space conditions, fire-safety requirements or lighting function.

Adapting to these factors, we plan the optimal execution for your hall, whether it be a sectional door, overhead door, high-speed door or fire door.

Windows and wall window strips

For windows and wall window strips, the manufacturers offer a wide variety of materials, looks, and functions. This reaches from uninsulated polycarbonate glazing to plastic or aluminium windows to post/beam construction to large-area glazing or wall window strips with clear glass, Profilit glazing, polycarbonate glazing.

4 steps to your new building

Benefit from more than 40 years of experience in the field of industrial buildings.

How much does a PEM hall cost?

Individual pricing with PEM Buildings

The construction of a new factory building requires a very wide variety of steps to its completion. One of the first questions to frequently arise in the planning phase: How do I find out the investment costs for the erection of my new property?

The halls of PEM Buildings are individually planned for each customer according to their needs and wishes. The price of a new commercial or industrial hall depends on numerous factors, such as the location and the accompanying static requirements for snow and wind loads, the usage, and the equipment standards.

To calculate a guide price offer for your new building, you only need to tell the experts at PEM Buildings the most important key data on the planned hall construction project. Contact us today and you will swiftly receive your individual offer.

Make non-binding enquiries now

Frequently asked questions on the subject of hall construction

When will my hall be delivered?

We will deliver your hall in a delivery time of 10 to 14 weeks.

How long does the construction time last, until the hall is ready to move into?

The construction time for the hall depends on its execution and size. As an approximate value, one can expect between 5 and 8 weeks per 1,000 m² for a steel hall from the top edge of the foundation.

Do you also offer a foundation slab?

Only in PEM general contractor projects is a foundation slab offered as requested.

Which type of hall construction is the most economical? (Gabled or pent roof, foil or panel roof, …)

Panel roof:

A panel roof is always the cheapest variant, regardless of whether a gabled or pent roof is used. This execution is suitable for warehouses and production halls that have no special requirements as regards architecture and fire safety.

Foil roof:

Large-area hall constructions are built with foil roofs. This avoids internal gutters and delivers a very high-quality standard. For this we use exclusively products from big-name manufacturers; work with them is carried out by our foil specialists. In combination with a maintenance contract we will give you a 10-year promise of guarantee. In comparison to the panel roofs, one should expect to pay between 20.00 to 35.00 EUR/m² more.

What will my standard hall cost per m²?

This depends on several parameters:

- Location of the building (snow load)

- Additional loads (PV system, hall crane)

- Span widths of the frameworks (hall width)

- Execution of the roof and wall cladding (insulated/uninsulated)

- Installations (doors, gates, skylights, hall crane, etc.)

Depending on the configuration of the steel hall the investment costs/m² from the top edge of the foundations vary in the range from 160.00 to 450.00 EUR/m²

Where can I take a look at a PEM steel hall?

In the course of 44 years PEM has erected more than 3,000 industrial and commercial buildings. There is bound to be an appropriate PEM steel hall near you.

If you are interested we will be happy to inform you of a reference near you and will also accompany you to the property.

Do you offer a warranty for your halls? For how long and for what?

It goes without saying that our customers can rely on the statutory warranty periods (Germany 4 years, Austria 3 years) for their hall construction.

For foil roofs we offer, in addition, a 10-year guarantee combined with a maintenance contract.

From what size in m² do you build halls?

We regard ourselves as a steel hall specialist and a quality partner for steel and system halls from a floor area of approx. 500 m².

Can you guarantee me a fixed price for my steel hall?

Yes, as your reliable construction partner it is important to us that you can rely on the agreed building budget. As well as the hall construction components, we already take into account in the offer all the cost-relevant items (lifting equipment, safety measures, waste disposal, etc.) which are required for the planning, production and assembly of your steel hall in line with quality requirements and standards. Once all details on the execution and scope of the hall construction have been clarified, we give an all-inclusive fixed price which guarantees that no unexpected additional costs arise for the customer.